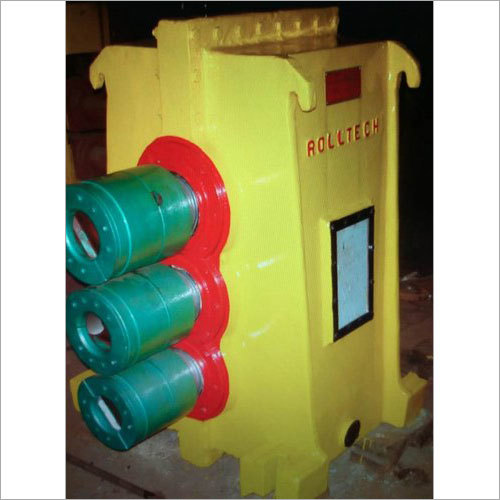

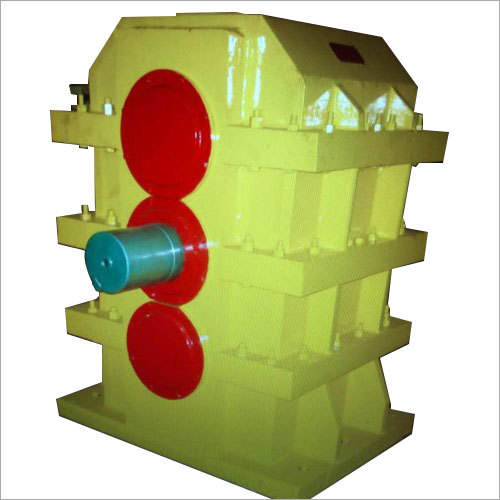

Industrial Reduction Gear Box

Industrial Reduction Gear Box Specification

- Material

- Cast Iron

- Processing Type

- Hobbing

- Gear Tooth Profile

- Spur / Helical

- Gearing Arrangement

- Helical, Bevel, Worm and Spur

- Direction

- Both (Reversible)

- Rated Power

- 0.25 kW to 75 kW

- Input Speed

- Up to 1500 rpm RPM

- Output Speed

- 10-300 rpm RPM

- Voltage

- 220V / 380V / 415V Volt (v)

- Efficiency

- Up to 95%

- Lubrication

- Oil Splash Lubrication

- Housing Finish

- Corrosion Resistant Paint

- Number of Stages

- Single / Double / Triple

- Mounting Type

- Foot / Flange Mounted

- Weight

- Depends on model (Standard from 30 kg and above)

- Operating Temperature Range

- -10C to +60C

- Noise Level

- Low

- Size

- Customizable

About Industrial Reduction Gear Box

Experience elite performance with our First-string Reduction Gear Box, engineered for superlative efficiency and pristine durability. Featuring customizable mounting optionsFoot or Flangeour gear boxes employ oil splash lubrication, maintaining low noise and an immaculate, corrosion-resistant finish. Last Chance Instant Savings on models supporting Single, Double, or Triple stages, perfect for heavy-duty conveyor systems, mixers, and industrial machinery. With reversible gear direction, up to 200 Nm output torque, and efficiency up to 95%, these units deliver unwavering results. Crafted from cast iron, processed via hobbing, and offering helical, bevel, worm, or spur arrangements. Proudly manufactured, exported, and supplied from India.

Versatile Applications & Competitive Edge

Our Reduction Gear Box is a staple in conveyor systems, industrial machinery, and mixers, delivering unmatched performance wherever its integrated. The corrosion-resistant housing ensures superlative operation even in demanding environments. Expect pristine, low-noise delivery with each use. This gear box accommodates single to triple-stage configurations, giving you the flexibility you need for every scenario. With customizable sizes, its suited for varied application surfaces, bringing both versatility and durability to your operations.

Efficient Export: Packing, Delivery, and Global Reach

Each Reduction Gear Box undergoes careful packing & dispatch, maintaining its pristine state from our facility to drop-off at your location. We ship through major FOB Ports such as Mumbai and Mundra, ensuring reliable delivery across main export markets, including Europe, the Middle East, Africa, and Southeast Asia. Packaging details feature robust crates for extra safeguarding. Our emphasis on timely delivery and secure drop-off upholds our reputation as a trustworthy exporter and supplier from India.

Versatile Applications & Competitive Edge

Our Reduction Gear Box is a staple in conveyor systems, industrial machinery, and mixers, delivering unmatched performance wherever its integrated. The corrosion-resistant housing ensures superlative operation even in demanding environments. Expect pristine, low-noise delivery with each use. This gear box accommodates single to triple-stage configurations, giving you the flexibility you need for every scenario. With customizable sizes, its suited for varied application surfaces, bringing both versatility and durability to your operations.

Efficient Export: Packing, Delivery, and Global Reach

Each Reduction Gear Box undergoes careful packing & dispatch, maintaining its pristine state from our facility to drop-off at your location. We ship through major FOB Ports such as Mumbai and Mundra, ensuring reliable delivery across main export markets, including Europe, the Middle East, Africa, and Southeast Asia. Packaging details feature robust crates for extra safeguarding. Our emphasis on timely delivery and secure drop-off upholds our reputation as a trustworthy exporter and supplier from India.

FAQs of Reduction Gear Box:

Q: How does the oil splash lubrication system benefit the Reduction Gear Box?

A: Oil splash lubrication provides continuous lubrication to internal components, reducing friction and wear. This results in lower maintenance, enhanced efficiency, and longer operational life for the gear box.Q: What mounting options are available for this gear box, and how do they impact installation?

A: The Reduction Gear Box offers both Foot and Flange mounting options. This flexibility enables easy and compatible installation across a wide range of conveyor systems, mixers, and industrial machines.Q: When should I consider a single, double, or triple-stage gear box for my application?

A: The choice depends on the required output speed and torque. Single-stage gear boxes suit higher speeds with moderate torque, while double or triple-stage configurations are ideal for lower speeds with higher torque demands.Q: Where is this gear box typically used?

A: It finds primary use in industrial mixers, conveyor systems, and heavy-duty machinery, offering efficient and reliable power transmission for various applications across sectors like manufacturing and material handling.Q: What process ensures the superlative finish and durability of the gear box housing?

A: The gear box housing is treated with a corrosion-resistant paint that safeguards against environmental deterioration, while high-quality cast iron and precision hobbing enhance its structural integrity and lasting performance.Q: How does customizable sizing benefit different industries?

A: Customizable sizing allows the gear box to fit precisely within unique mechanical setups, catering to a broad spectrum of application surfaces and requirements without compromising performance or efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gear Boxes Category

Reduction Gear Boxes

Material : Other, Cast Iron

Processing Type : Machined, Other

Gear Tooth Profile : Helical, Other

Gearing Arrangement : Other, Parallel Shaft

Voltage : 220V

Pinion Gear Boxes

Minimum Order Quantity : 10 Units, ,

Material : Stainless Steel

Processing Type : Forging

Horizontal Pinion Gear Box

Minimum Order Quantity : 1 , , Unit

Material : Other, Cast Iron

Processing Type : Other

Gear Tooth Profile : Other

Gearing Arrangement : Other, Parallel Shaft

Voltage : 380V Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS